Delving into the realm of high-efficiency electric motors for industry use unveils a world where innovation meets practicality, transforming the landscape of industrial operations. This exploration promises to shed light on the pivotal role these motors play in enhancing efficiency and sustainability within various sectors.

Overview of High-efficiency Electric Motors for Industry Use

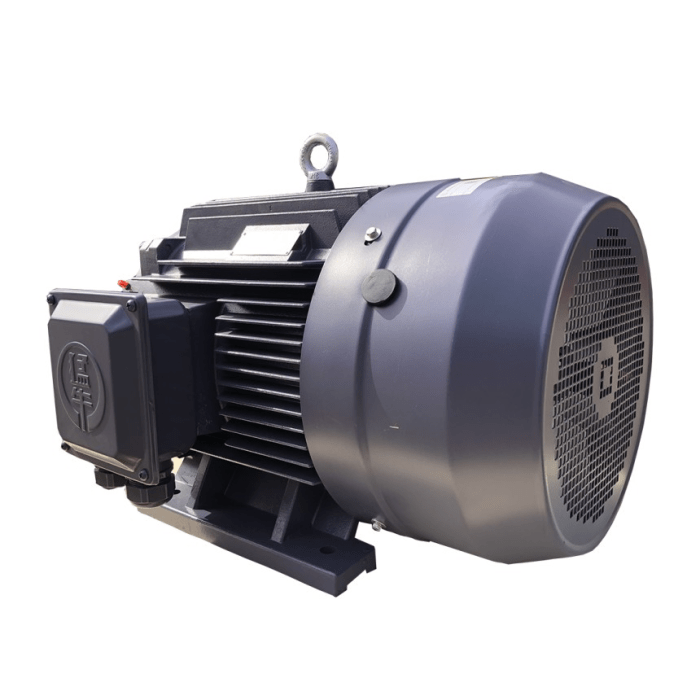

Electric motors play a crucial role in various industrial applications, powering machinery and equipment essential for production processes. High-efficiency electric motors are specifically designed to minimize energy loss and optimize performance, making them highly sought after in industrial settings. These motors are characterized by their ability to convert a higher percentage of electrical energy into mechanical power, resulting in reduced energy consumption and operating costs.

Key Characteristics of High-efficiency Electric Motors

- Improved Design: High-efficiency motors are engineered with advanced materials and precision components to enhance performance and reliability.

- Lower Energy Losses: These motors are built with tighter tolerances and superior insulation to minimize energy losses through heat dissipation.

- Efficient Cooling Systems: High-efficiency motors often feature innovative cooling systems that help maintain optimal operating temperatures, further enhancing their efficiency.

- Variable Speed Capabilities: Many high-efficiency motors are equipped with variable frequency drives (VFDs) to adjust speed based on specific application requirements, reducing energy waste.

Importance of Energy Efficiency in Industrial Settings

Energy efficiency is a critical factor for industries looking to reduce their environmental impact and operating costs. By opting for high-efficiency electric motors, companies can significantly lower their energy consumption, leading to decreased greenhouse gas emissions and improved sustainability. These motors not only help organizations meet regulatory standards but also contribute to long-term cost savings and a more sustainable future for the industry.

Types of High-efficiency Electric Motors

Electric motors are a crucial component in various industries, providing power for a wide range of applications. When it comes to high-efficiency motors, there are several types commonly used, each with its unique features and benefits. Let's explore and compare these different types to understand where they are most suitable and their advantages.

Induction Motors

Induction motors are widely used in industries due to their robustness and reliability. They operate on the principle of electromagnetic induction, where a rotating magnetic field is produced to drive the rotor. These motors are suitable for applications requiring constant speed operation, such as pumps, fans, and compressors.

Permanent Magnet Motors

Permanent magnet motors utilize permanent magnets to create the rotor's magnetic field, eliminating the need for external power to generate a magnetic field. These motors are known for their high efficiency and power density, making them ideal for applications where space is limited, such as in electric vehicles and robotics.

Synchronous Reluctance Motors

Synchronous reluctance motors are designed to optimize the reluctance torque by shaping the rotor and stator to achieve high efficiency. These motors are best suited for applications requiring variable speed operation and high efficiency, such as in industrial automation and HVAC systems.Each type of high-efficiency electric motor offers unique advantages and is suitable for different industrial applications based on their specific characteristics and performance capabilities.

Design and Construction of High-efficiency Electric Motors

Electric motors used in industrial applications are designed with efficiency in mind to maximize performance and energy savings. Manufacturers consider various factors during the design process to optimize the efficiency of these motors.

Design Considerations for Optimizing Efficiency

- Efficient use of materials: Manufacturers carefully select materials that reduce energy losses due to friction and heat, such as high-quality copper windings and low-loss magnetic materials.

- Aerodynamic design: Motor housings are designed to minimize air resistance and improve cooling, ensuring optimal performance.

- Precision engineering: Tight tolerances and accurate machining of components reduce energy losses and increase overall efficiency.

- Optimized winding configurations: Different winding configurations are used to reduce losses and improve motor efficiency under varying load conditions.

Materials Used in Construction

- Copper: High-efficiency electric motors often use copper windings due to their excellent conductivity, reducing energy losses.

- Permanent magnets: Some motors incorporate rare-earth magnets for improved performance and efficiency.

- Steel laminations: Silicon steel laminations are commonly used in motor cores to reduce eddy current losses and increase efficiency.

Advancements in Motor Design

- Improved cooling systems: Enhanced cooling mechanisms such as liquid cooling or advanced fan designs help maintain optimal operating temperatures and improve motor efficiency.

- Variable frequency drives (VFDs): Integration of VFDs allows for better control of motor speed and reduces energy consumption by matching motor output to the required load.

- Advanced control algorithms: Smart motor controllers incorporate sophisticated algorithms to optimize motor performance and efficiency based on real-time operating conditions.

Applications and Benefits of High-efficiency Electric Motors

Electric motors are vital components in various industries, and the shift towards high-efficiency models has brought significant advantages. Let's explore some specific applications and benefits of high-efficiency electric motors in industry.

Specific Industries and Advantages

In industries such as manufacturing, HVAC, agriculture, and transportation, high-efficiency electric motors are extensively used to power various equipment and processes. The primary advantage of these motors is their ability to convert electrical energy into mechanical energy with minimal losses, leading to reduced energy consumption and cost savings.

For example, in manufacturing plants, the implementation of high-efficiency motors has resulted in improved operational efficiency, reduced downtime, and lower maintenance costs.

Cost Savings and Operational Efficiency

The adoption of high-efficiency electric motors has proven to be a wise investment for many industrial facilities. By reducing energy waste and optimizing performance, these motors help companies lower their electricity bills and overall operational costs. Real-world examples include a textile factory that saved 20% on energy costs after switching to high-efficiency motors and a food processing plant that increased production output by 15% while reducing energy consumption by 10%.

Environmental Benefits

Apart from cost savings, high-efficiency electric motors also offer significant environmental benefits. By consuming less energy to deliver the same output as standard motors, they contribute to a reduction in carbon emissions and promote sustainability. This is especially crucial in industries with high energy consumption rates, such as mining and construction, where the use of high-efficiency motors can help mitigate environmental impact and support green initiatives.

Conclusion

In conclusion, the journey through high-efficiency electric motors for industry use has illuminated the path towards a more energy-efficient and environmentally conscious future for industrial practices. Embracing these advanced technologies is not just a choice but a necessity in today's rapidly evolving industrial landscape.

Common Queries

What makes high-efficiency electric motors different from standard motors?

High-efficiency electric motors are designed to minimize energy loss during operation, leading to reduced energy consumption and cost savings in the long run.

Which industries benefit the most from the use of high-efficiency electric motors?

Industries such as manufacturing, automotive, and HVAC systems benefit significantly from the enhanced performance and energy savings offered by high-efficiency electric motors.

How do advancements in motor design contribute to increased efficiency in industrial applications?

Advancements in motor design focus on reducing friction, optimizing materials, and enhancing electronic controls, resulting in higher efficiency and reliability in industrial settings.